STYLE 600 SLEEVELESS

We are proud to introduce the result of our most intensive engineering research into sealing devices.

This is the first mechanical seal which incorporates a conical stuffing box design, allowing this seal to be used with great success on slurries and dirty fluids.

Until now all mechanical cartridge seals have been designed with an integral shaft sleeve. This revolutionary sleeveless design allows for installation on pumps where it was previously considered impossible to install a cartridge mounted seal. The sleeveless design also allows for greater radial run-out of the shaft.

With no seal parts inside the stuffing box, slurry and dirt cannot clog the seal therefore increasing seal life. This new seal also incorporates a gland plate with flushing connection and large, solid seal faces manufactured from sintered materials mounted on flexible elastomers, which also act as shock absorbers.

This seal offers great reliability under the harshest of working conditions. The highly competitive cost of both the seal and the spare parts, when compared with other cartridge mounted mechanical seals, offers the user real cost benefits and makes this the only real innovation in the sealing market for many years.

- Gland with integrated features of conical stuffing box and flushing

- No seal parts inside pump stuffing box

- Dynamic elastomer working on sintered ceramic materials "Fretting corrosion" free

- Multiple springs out of the fluid

- Conical shape of stationary face with wide room for misalignments compensation and not allowing any clogging

- Hydraulically balanced monolithic stationary face computer designed with F.E.A. (Finit Element Analysis)

- Extremely compact dimensions

- Static elastomer with shock absorbing feature

Technical Data |

Technical Data

|

| MATERIALS |

| Metal parts: |

AISI 316 T |

| Springs: |

Hastelloy* C - 273 |

| Sliding faces: |

Carbon RC - Silicon Carbide (self-sintered) |

| Tungsten Carbide (Ni - bound) |

| Silicon Carbide RB |

| Elastomers: |

Viton? 747-75 - EPR - Kalrez? |

| HY-REZ? - Chemraz? |

| Other materials available upon request. |

| APPLICATIONS |

| Temperature: |

Up to elastomer limit |

| *Viton? |

+205 ?C max |

| *E.P.R.? |

+150 ?C max |

| *Kalrez? |

+315 ?C max |

| * upon shaft diameter and speed |

| Max pressure: |

Vacuum 700 mm Hg ? 3.5 Mpa |

| Speed: |

25 m/sec (depending on materials of sliding faces) |

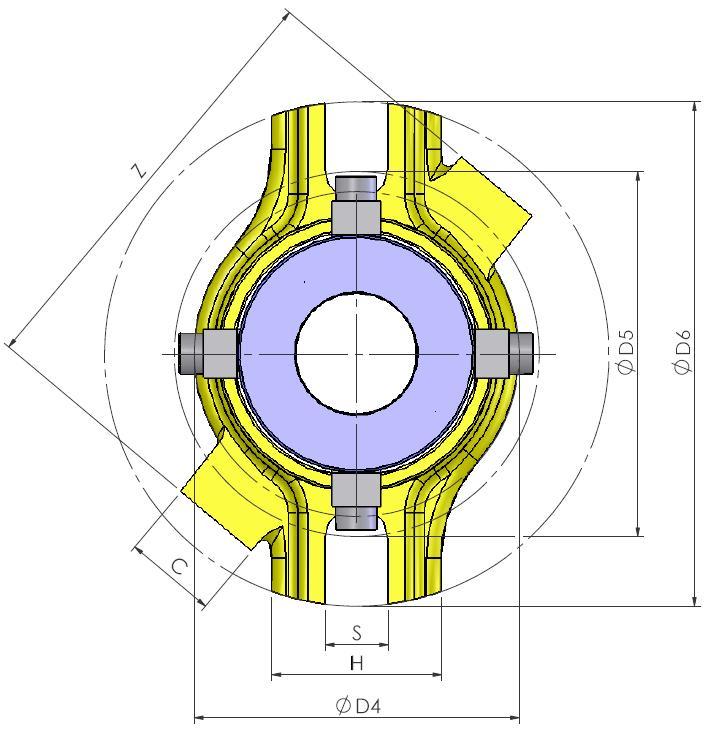

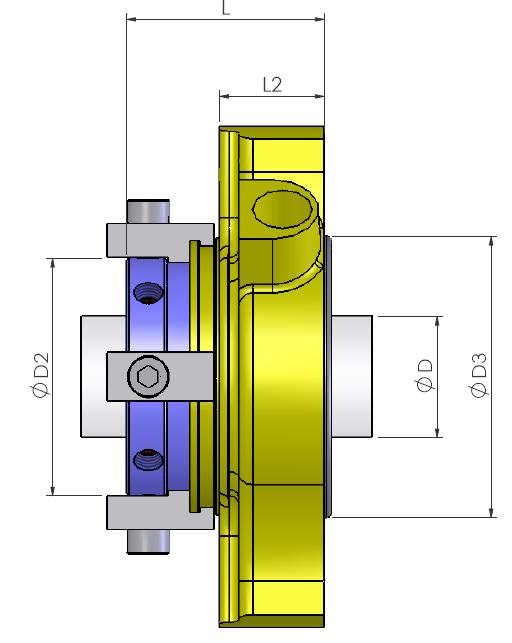

| DIMENSIONS |

| Imperial: |

1¨ - 3¨? |

Metric: |

24 - 80 mm |

| D |

D2 |

D3 |

D4 |

D5 |

D6 |

L |

L2 |

C |

H |

S |

Z |

| 24 |

42 |

58 |

67 |

76 |

104 |

41 |

22.5 |

19 |

35 |

13 |

90 |

| 25 |

42 |

58 |

67 |

76 |

104 |

41 |

2.5 |

19 |

35 |

13 |

90 |

| 28 |

42 |

61 |

67 |

76 |

104 |

41 |

23 |

19 |

35 |

13 |

90 |

| 30 |

54 |

63 |

72 |

80 |

110 |

41 |

21.5 |

19 |

37 |

13 |

94 |

| 32 |

54 |

65.5 |

72 |

80 |

110 |

41 |

21.5 |

19 |

37 |

13 |

94 |

| 33 |

54 |

65.5 |

72 |

80 |

110 |

41 |

21.5 |

19 |

37 |

13 |

94 |

| 35 |

61 |

68 |

81 |

89 |

128 |

41 |

21.5 |

19 |

37 |

13 |

102 |

| 38 |

61 |

70 |

81 |

89 |

128 |

41 |

21.5 |

19 |

37 |

13 |

102 |

| 40 |

61 |

72.8 |

81 |

89 |

128 |

41 |

21.5 |

19 |

37 |

13 |

102 |

| 42 |

65 |

75 |

86 |

100 |

142 |

41 |

21.5 |

19 |

38 |

14 |

106 |

| 43 |

65 |

75 |

86 |

100 |

142 |

41 |

21.5 |

19 |

38 |

14 |

106 |

| 45 |

65 |

77.8 |

86 |

100 |

142 |

41 |

21.5 |

19 |

38 |

14 |

106 |

| 48 |

74 |

82.8 |

95 |

106 |

154 |

41 |

21.5 |

19 |

43 |

17 |

116 |

| 50 |

74 |

82.8 |

95 |

106 |

154 |

41 |

21.5 |

19 |

43 |

17 |

116 |

| 53 |

74 |

87 |

95 |

106 |

154 |

41 |

21.5 |

19 |

43 |

17 |

116 |

| 55 |

80 |

87 |

104 |

120 |

172 |

41 |

21.5 |

19 |

45 |

17 |

124 |

| 58 |

80 |

93 |

104 |

120 |

172 |

41 |

21.5 |

19 |

45 |

17 |

124 |

| 60 |

80 |

93 |

104 |

120 |

172 |

41 |

21.5 |

19 |

45 |

17 |

124 |

| 65 |

87 |

101.5 |

124 |

134 |

180 |

45 |

26.5 |

19 |

53 |

17 |

136 |

| 70 |

87 |

107 |

124 |

134 |

180 |

50 |

26.5 |

19 |

53 |

17 |

136 |

| 75 |

113 |

120.5 |

136 |

148 |

200 |

50 |

26.5 |

19 |

59 |

19 |

148 |

| 80 |

114 |

130 |

136 |

148 |

200 |

50 |

26.5 |

19 |

59 |

19 |

148 |

|

| |